Posts Tagged ‘CNC’

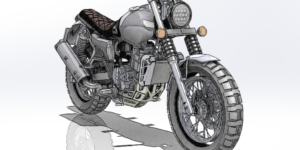

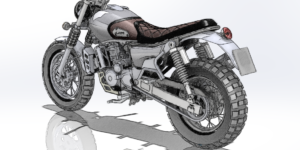

UM RENEGADE SCRAMBLER 300W

The UM RENEGADE SCRAMBLER 300W is a prototype (showbike) created for UM Global on the basis of their product currently on the market, the RENEGADE COMMANDO.

Of the original motion of course we had to keep as many parts as possible to optimize the entire engineering process and put into production, we also have reused some of actual production parts UM so consertire company an advantageous economy of scale.

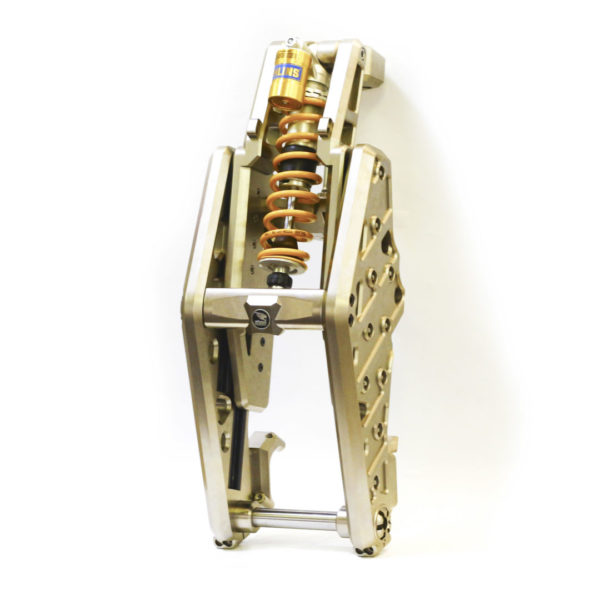

The main change has obviously affected the new wheel sizes ( 120/70 R19 Ant. e 170/60 R17 Post.) we had to use to give the bike a new enduro trim, We then re-radiated existing hubs with a new set of Takasago Excel and mounted the panciutissimi and tassellatissimi Continental TKC 80.

Similarly we had to intervene to lift the bike on set, then the back we opted for a couple of shock absorbers 380mm, while the fork has remained the series to limit investment.

For superstructures we drew with pleasure by those who are the componentistic serial production UM, always at the highest level considered to be the end of the market, mixing classical elements with more modern parts, and in some cases "disruptive" as the underride protection in 4mm sheet made with our technique "Sheet-Box". We also experienced a first in the motorcycle field, namely the creation of wooden components made from 3D design through numerically controlled milling (CNC), and made of "cheeks" tank with a perfect shape bearing on the surfaces of the original tank and some details in the rear area.

The rest of the parts are made in 3D printing but also by local artisans, the beautiful leather upholstery is an example, but also the sheet metal mudguards do not joke.

The bike was presented at EICMA motorcycle show in Milan 2018 and according to many is one of the most exciting features that are seen.

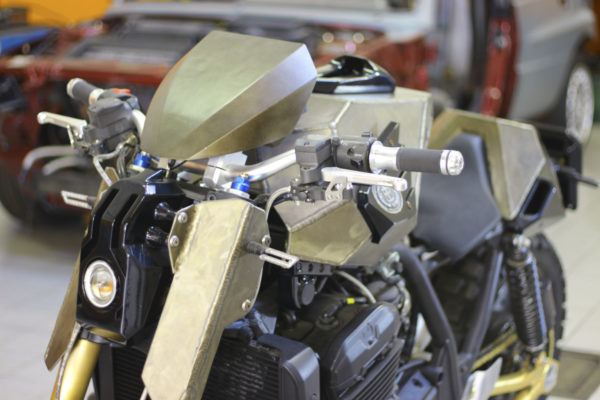

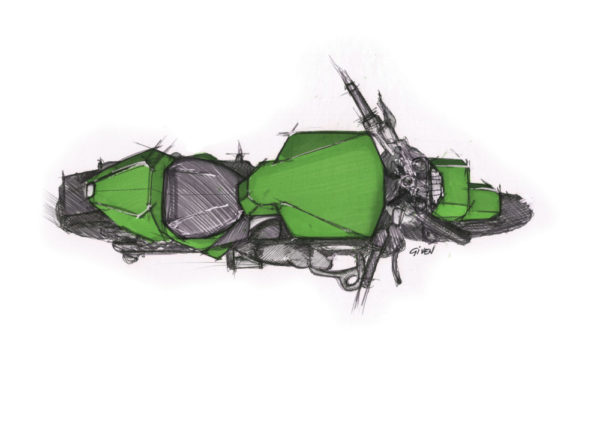

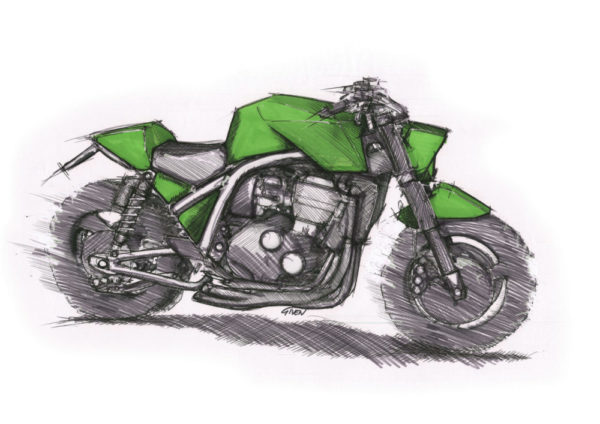

Kawasaki ZXR 1100 “STEALTH”

A classic reissued in a modern post / Atomic!

Created for and with "Officine Riunite Milanesi" from a Kawasaki ZXR 1100, "Lamaialona" It is a deliberately strong design studio on a very simple basis.

Created for and with "Officine Riunite Milanesi" from a Kawasaki ZXR 1100, "Lamaialona" It is a deliberately strong design studio on a very simple basis.

Tired of the same interpretations in key Cafè Racer, Scrambler o Hypster, we opted for an interpretation that would allow us to do both formal experimentation both of techniques and materials used.

The initial idea was a bike in Stealth Style, literally "stealth, clandestinely", We then tried to apply this concept to a national typical military means or otherwise road, of course we focused on the typical square shape of this design, on sharp edges and on the technical nature of the global design. also from "jargon" military have inherited the performance of all types of soils, from pure off-road to the runway, equipping the means of a highly efficient cycling system, replacing suspensions, wheels and braking system. The latter has been realized ad hoc according to our design from "Discacciati Brake System" Thank you for joining us in this trial involving, always with the highest standards of reliability and safety criteria, a component so exclusively technical and functional as the braking system.

A motorcycle show and the Futa Pass

The bike is designed as a whole as an element of design research for future motorcycle trends both of mass production but also of private interpretation staff, we believe the result of this experiment is certainly positive, we saw that you can produce a half from the strong mechanical characterization without appearing a Rat-bike or an old tractor just emerged from years of lethargy in a barn. The result however is a bike that is very well suited for both heavy duty use, as an excursion long haul, or a ride in the hills or one stressful Futa Pass. But at the same time you can use "Lamaialona" as a daily means of transport or as a simple motion "bar".

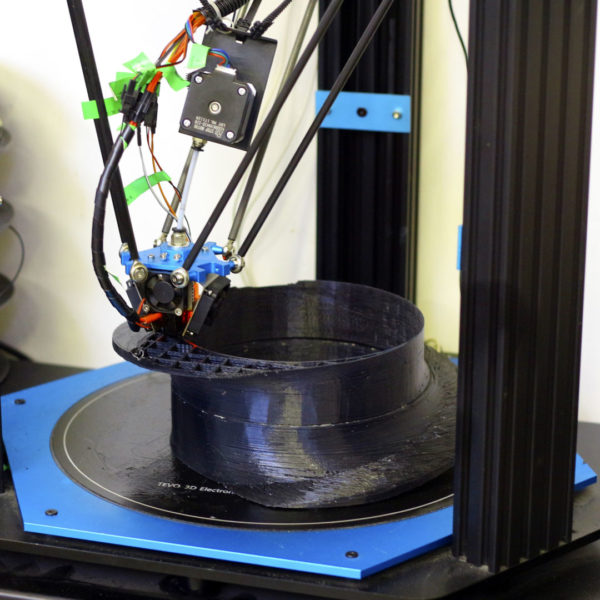

3D Print

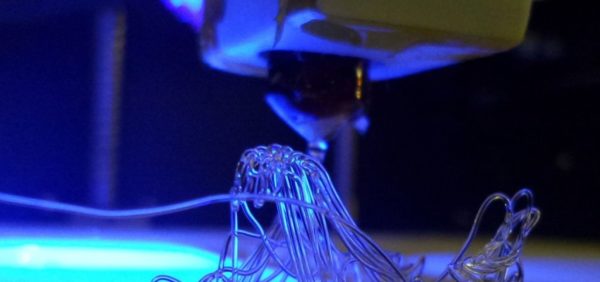

Lamaialona was realized with the help of modern 3D design and printing systems. The first step was to bring the bike on your computer, so here we proceeded to the three-dimensional scanning as soon as the half came in the workshop, the time to remove all the superstructures and 5 minutes we had a beautiful cloud of points which allowed us to proceed to the design with a full big picture.

Once we defined the style we started with the implementation of the various parties. In the first instance we have used our 3D printers to verify that the parts were assembled correctly.

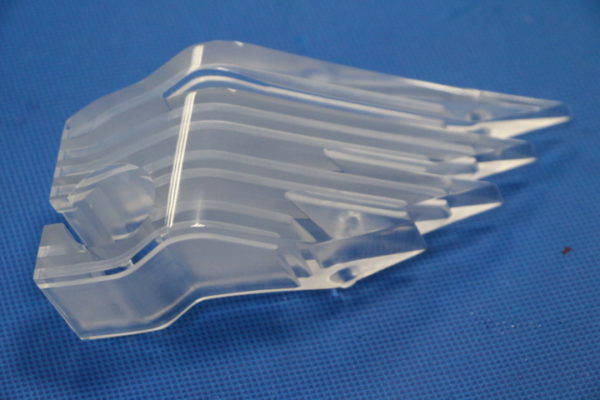

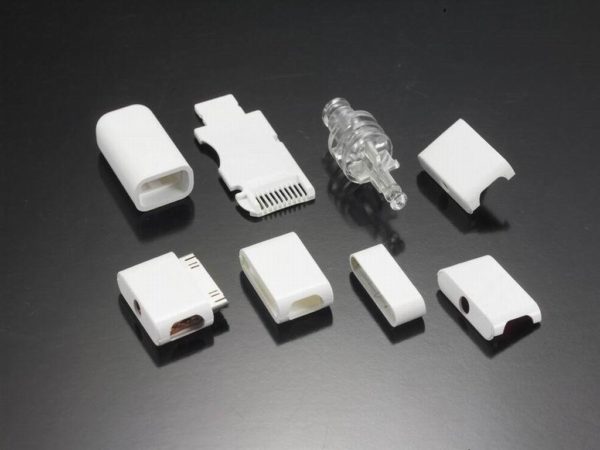

The bike was then created with a mixture of techniques, digital design and more practical manuals. After scanning all the pieces they were designed in 3D, but then the aluminum sheet metal parts have been cut out and welded by hand, All plastic parts instead are designed based on criteria of feasibility in the CNC for future reproductions and then implemented using FDM 3D printing. At that point a good coat of paint and here the pieces ready for installation.

The fairing instead was made from a single block of aluminum 6061 via CNC milling, this in order to obtain a very often without the classic defect of thin gauge sheet metal edge with exposed edge.

Omologabilità

The whole bike has been designed based on criteria of relevance perfect homologation, therefore it is perfectly "code compliant" according to EC DIRECTIVES (2002/24/THIS). All the lights are approved and positioned geometrically correct position, the same applies for license plate and all other accessories shown. Similarly the mechanical parts are ready to positively overcome the homologation tests related (tank, tripod etc.).

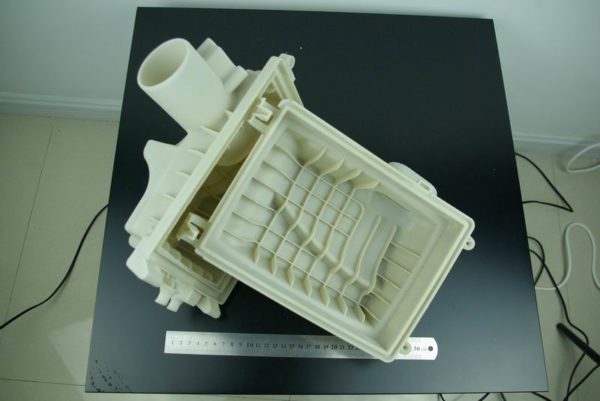

3D Print – Prototyping, CNC and fast technologies

Prototyping is a key component of our work, we use it to evaluate the goodness of the pieces designed before proceeding with the actual construction, the use for small series of pieces where it is not justified the cost of a mold, we use it to make an initial visual assessment, functional, dimensional.

For some prototypes we are organized in house in order to make fast the first phase of testing, other features will provide some specialist suppliers with whom we have a direct line and thanks to which we are developing a lot of knowledge in this sector still strong growth.