Clay

One of the most important steps in motorcycle design is certainly build a model "Clay".

The so-called "automotive clay" It is a synthetic clay developed in the 70s specifically for the transportation design sector, It has the characteristic, compared to clay (Clay editor's note) Traditional to be reshaped infinite number of times and being thermoplastic, then soft and mouldable at the working temperature (55/65 degrees) is hard, compact and milled at ambient temperature.

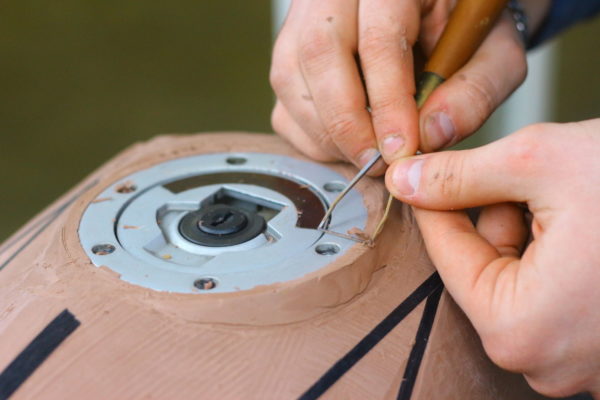

This allows maximum freedom to the modeler, and it allows him to be able to give to the artifact exactly the desired shape, with a precision of a few tenths of a millimeter by simply using the modeling tools or removal.

Once we achieved the desired shape can proceed with an evaluation stage via "HighLight Wall", where by means of special lights and special coatings (in film or paint) we can evaluate the formal correctness of the surface. The other evaluation we can do, together with the customer is obviously the aesthetic and ergonomic, checking that the shape and the volumes are correct, engaging and proportionally fair.

If changes were to be requested, It will not be a problem, return to "Clay Room" and reshaping the object according to the new criteria.

The Clay is a very long and complex process, that requires much skill and dexterity, also it requires a two-phase computer design, in the first instance in the style of phase with a CAS / CAM analysis which allows to have a clear idea of what we are to achieve, and derive suitably dimensioned media, Finally, in the final abutment of the surface it requires a transformation process in the 3D model (Reverse Engineering), it also very long and complex, so its cost is definitely high and it is recommended (in our opinion) only in some cases it is not possible to proceed with the most direct ways.